[Get the best value hook loop tape on Amazon today!]

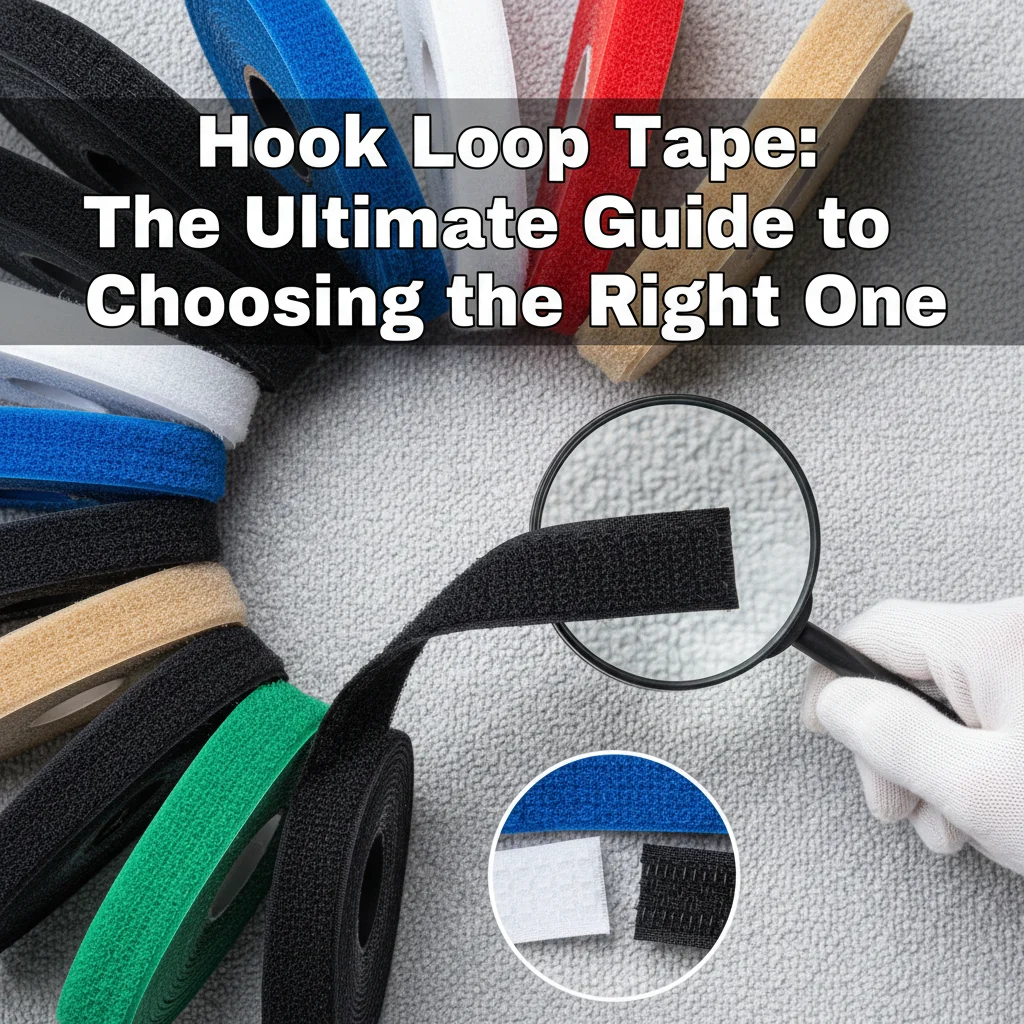

# Hook Loop Tape: The Ultimate Guide to Choosing the Right One

Are you tired of messy cables, disorganized tools, or fabrics that just won’t stay put? Hook and loop tape, often referred to by the brand name Velcro, is a simple yet incredibly versatile solution to a wide range of fastening and organizing needs. But with so many different types, strengths, and adhesives available, choosing the right hook loop tape for your project can feel overwhelming.

This guide is here to demystify the world of hook loop tape. We’ll explore the various factors you need to consider to make the perfect choice, ensuring your projects are secure, organized, and long-lasting. Whether you’re a seasoned crafter, a DIY enthusiast, or simply looking for a better way to manage clutter, this ultimate guide will give you the knowledge you need to confidently select the right hook loop tape for any application.

[Browse top-rated hook loop tape on Amazon]

## Understanding Hook Loop Tape: The Basics

Before diving into the specifics of choosing the right hook loop tape, let’s cover the fundamentals. Hook and loop tape consists of two components: a “hook” side covered in tiny, stiff hooks and a “loop” side covered in soft, fuzzy loops. When pressed together, the hooks engage with the loops, creating a strong, yet easily separable bond. This simple mechanism has revolutionized fastening in countless industries and applications.

The strength of the bond depends on several factors, including the density of the hooks and loops, the materials used, and the surface area of the tape. Different types of adhesives are also used to attach the tape to various surfaces, further influencing its overall performance.

[Browse top-rated hook loop tape on Amazon]

## Key Factors to Consider When Choosing Hook Loop Tape

Choosing the right hook loop tape involves carefully considering the following factors:

* **Adhesive Type:** The adhesive is crucial for ensuring the tape stays securely attached to the intended surface.

* **Material:** The material of the hook and loop itself affects its strength, durability, and suitability for different environments.

* **Width and Length:** Selecting the appropriate width and length is essential for optimal performance and aesthetics.

* **Strength and Durability:** Consider the weight or stress the tape will need to withstand and choose a tape with adequate strength and durability.

* **Environmental Conditions:** Exposure to moisture, extreme temperatures, or UV radiation can affect the tape’s performance.

* **Intended Use:** The specific application will dictate the type of hook loop tape that is most suitable.

Let’s delve into each of these factors in more detail.

### Adhesive Type: Sticking to the Right Choice

The adhesive is arguably the most critical factor in choosing hook loop tape. The wrong adhesive can lead to premature failure, leaving you with a frustrating and ineffective solution. Here’s a breakdown of common adhesive types:

* **Rubber-Based Adhesives:** These adhesives offer excellent initial tack and bond well to a variety of surfaces, including paper, cardboard, and some plastics. They are generally best suited for indoor applications where temperature and humidity are relatively stable. However, they may not be as durable as other options in extreme conditions or when exposed to moisture.

* **Acrylic-Based Adhesives:** Acrylic adhesives are known for their durability, UV resistance, and ability to withstand a wider range of temperatures. They typically take longer to reach their full bonding strength compared to rubber-based adhesives but offer superior long-term performance. They are a good choice for both indoor and outdoor applications, especially those exposed to sunlight or fluctuating temperatures.

* **Solvent-Based Adhesives:** These are the heavy hitters of the adhesive world. Solvent-based adhesives offer exceptional strength, durability, and resistance to chemicals and extreme temperatures. They are often used in industrial applications where a permanent and reliable bond is essential. However, they may require special handling and ventilation due to the solvents used in their formulation.

* **Sew-On Hook Loop Tape:** For fabrics and textiles, sew-on hook loop tape is the most reliable option. This type of tape lacks adhesive backing and is designed to be sewn directly onto the fabric. This creates a permanent and incredibly strong bond that can withstand repeated washing and wear.

* **Pressure Sensitive Adhesives (PSA):** This is a general term covering both rubber and acrylic-based adhesives. PSA adhesives require pressure to form a bond. Ensure you apply firm, even pressure when applying hook loop tape with a PSA backing.

**Choosing the Right Adhesive:**

* **For general household use and crafting on paper or cardboard:** Rubber-based adhesives are often sufficient.

* **For outdoor applications, high-temperature environments, or use on plastics:** Opt for acrylic-based adhesives.

* **For heavy-duty industrial applications or where extreme durability is required:** Solvent-based adhesives are the best choice.

* **For fabrics and textiles:** Sew-on hook loop tape is the most reliable option.

### Material: Strength and Durability Matters

The material of the hook and loop components also plays a significant role in the tape’s overall performance. Common materials include:

* **Nylon:** Nylon is a popular choice for hook loop tape due to its excellent strength, durability, and resistance to abrasion. It’s suitable for a wide range of applications, including clothing, sporting goods, and industrial uses. Nylon hook loop tape is also relatively resistant to moisture and UV radiation.

* **Polyester:** Polyester is another durable and versatile material that offers good resistance to stretching and shrinking. It’s often used in applications where dimensional stability is important. Polyester hook loop tape is also more resistant to UV degradation than nylon, making it a good choice for outdoor applications.

* **Polypropylene:** Polypropylene is a lightweight and cost-effective material that offers good resistance to chemicals and moisture. However, it’s not as strong or durable as nylon or polyester and may not be suitable for heavy-duty applications.

**Choosing the Right Material:**

* **For general-purpose use and applications requiring high strength and durability:** Nylon is an excellent choice.

* **For outdoor applications or where dimensional stability is important:** Polyester is a good option.

* **For lightweight applications where cost is a primary concern:** Polypropylene may be suitable.

### Width and Length: Getting the Right Fit

The width and length of the hook loop tape are important considerations for both functionality and aesthetics.

* **Width:** Choose a width that is appropriate for the size of the objects you are fastening. Wider tape generally provides a stronger bond and is better suited for heavier items. Narrower tape is more discreet and may be preferable for smaller or more delicate items.

* **Length:** Cut the tape to the appropriate length for each application. Overlapping the tape can increase its strength, but excessive overlap can also create bulk and make it more difficult to separate.

**Tips for Choosing Width and Length:**

* **Consider the size and weight of the objects you are fastening.**

* **Choose a width that provides adequate surface area for a strong bond.**

* **Cut the tape to the appropriate length, allowing for slight overlap if desired.**

* **For adjustable applications, use longer strips of tape to allow for flexibility.**

### Strength and Durability: Holding Up Under Pressure

The strength and durability of hook loop tape are crucial factors to consider, especially for applications where the tape will be subjected to significant stress or repeated use.

* **Shear Strength:** Shear strength refers to the tape’s ability to resist forces that are parallel to the surface. This is important for applications where the tape will be subjected to sliding or pulling forces.

* **Tensile Strength:** Tensile strength refers to the tape’s ability to resist forces that are perpendicular to the surface. This is important for applications where the tape will be supporting weight or resisting pulling forces.

* **Cycle Life:** Cycle life refers to the number of times the hook and loop can be engaged and disengaged before its performance degrades. This is important for applications where the tape will be repeatedly opened and closed.

**Choosing the Right Strength and Durability:**

* **For lightweight applications with minimal stress:** Standard hook loop tape is usually sufficient.

* **For heavy-duty applications or those subjected to significant stress:** Choose industrial-strength hook loop tape.

* **For applications requiring repeated opening and closing:** Select a tape with a high cycle life.

### Environmental Conditions: Weathering the Storm

Exposure to moisture, extreme temperatures, or UV radiation can significantly affect the performance of hook loop tape.

* **Moisture Resistance:** Some adhesives and materials are more resistant to moisture than others. For outdoor applications or those exposed to humidity, choose a tape with good moisture resistance.

* **Temperature Resistance:** Extreme temperatures can cause some adhesives to soften or become brittle. Choose a tape that is rated for the temperature range it will be exposed to.

* **UV Resistance:** Prolonged exposure to UV radiation can cause some materials to degrade and lose their strength. For outdoor applications, choose a tape with good UV resistance.

**Choosing the Right Tape for Environmental Conditions:**

* **For indoor applications in stable environments:** Standard hook loop tape is usually sufficient.

* **For outdoor applications or those exposed to extreme conditions:** Choose a tape specifically designed for outdoor use.

### Intended Use: Matching the Tape to the Task

The specific application will dictate the type of hook loop tape that is most suitable. Here are some common applications and the recommended types of tape:

* **Crafting and Sewing:** For lightweight projects, standard hook loop tape with a rubber-based adhesive or sew-on tape is often sufficient. For heavier projects or those requiring more durability, choose a tape with an acrylic-based adhesive or nylon construction.

* **Organizing and Cable Management:** Standard hook loop tape with a rubber

[Check the latest prices and deals for hook loop tape on Amazon today!]