[Get the best value jewelry casting on Amazon today!]

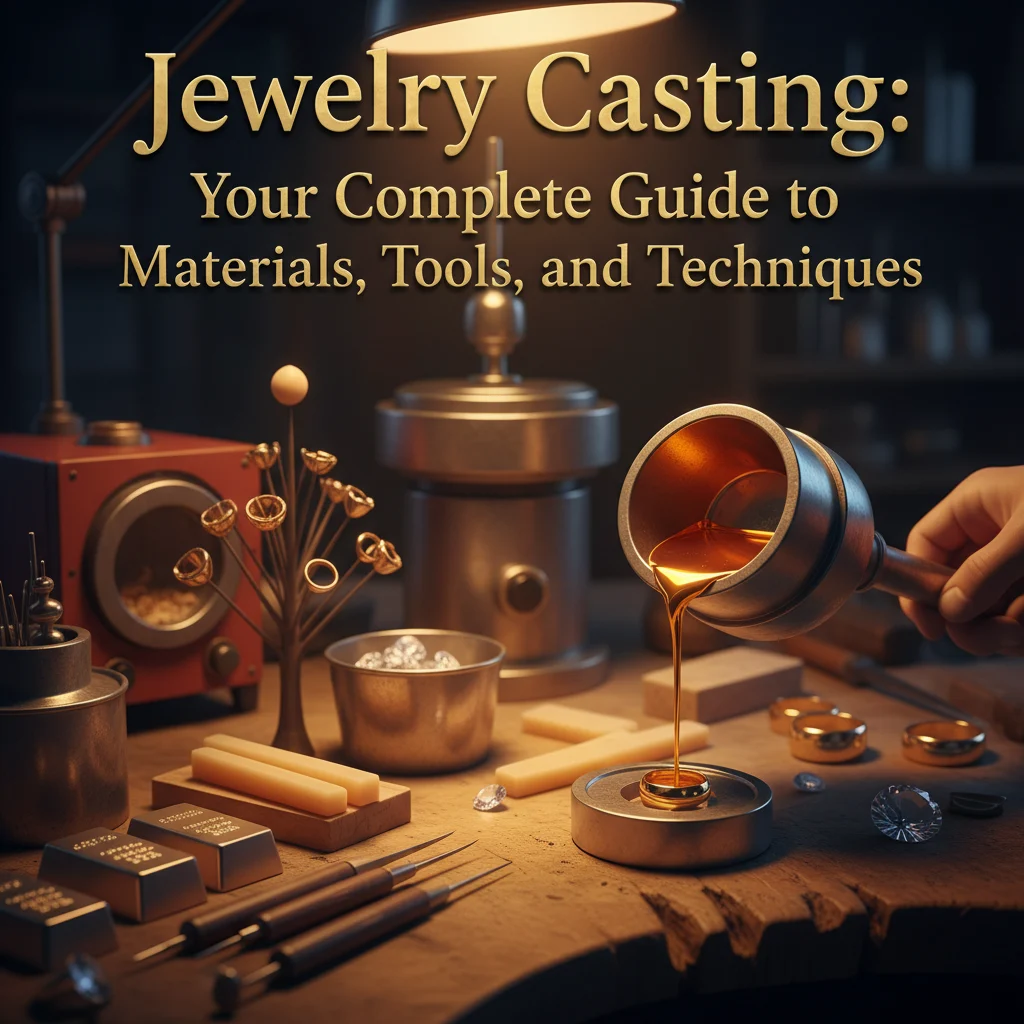

# Jewelry Casting: Your Complete Guide to Materials, Tools, and Techniques

So, you’re ready to dive into the fascinating world of jewelry casting! Whether you’re a seasoned artisan looking to refine your techniques or a complete beginner eager to create your first piece, this guide is your one-stop resource. We’ll cover everything you need to know, from selecting the right materials and tools to mastering essential jewelry casting techniques. Get ready to transform your creative visions into tangible, wearable art!

[Browse top-rated jewelry casting on Amazon]

## What is Jewelry Casting?

Jewelry casting is the process of creating jewelry by pouring molten metal into a mold. This mold is typically created from a wax model, which is then burned out to leave a cavity ready for the molten metal. It’s a versatile technique that allows you to replicate intricate designs and create multiple copies of the same piece. While it might sound complex, with the right knowledge and tools, jewelry casting is accessible to anyone with a passion for crafting.

[Browse top-rated jewelry casting on Amazon]

## Materials You’ll Need for Jewelry Casting

Choosing the right materials is crucial for successful jewelry casting. Here’s a breakdown of the essential materials:

* **Metals:** The most common metals used in jewelry casting are sterling silver, gold, bronze, and brass. Each metal has its own unique properties, affecting its color, durability, and melting point.

* **Sterling Silver:** A popular choice for its affordability and bright, shiny appearance. It requires a higher level of care to prevent tarnishing.

* **Gold:** A classic choice known for its beauty, durability, and resistance to tarnishing. Gold is available in various karats (purity levels), each with different properties.

* **Bronze:** Offers a warm, reddish-brown hue and is relatively easy to cast.

* **Brass:** A more affordable alternative to gold, offering a bright yellow color.

* **Wax:** Wax is used to create the initial model of your jewelry piece. Different types of wax are available, each with its own properties.

* **Carving Wax:** A hard wax ideal for carving intricate details.

* **Injection Wax:** A softer wax designed for injection into rubber molds.

* **Sheet Wax:** A thin wax used for creating flat or slightly curved designs.

* **Investment:** Investment is a plaster-like material used to create the mold around the wax model. It needs to be heat-resistant and capable of withstanding the high temperatures of the burnout process.

* **Crucible:** A crucible is a heat-resistant container used to melt the metal. Choose a crucible that is compatible with the type of metal you’re using and the size of your casting project.

* **Flux:** Flux is a chemical compound used to prevent oxidation during the melting process. It helps to create a clean, smooth casting.

[Browse top-rated jewelry casting on Amazon]

## Essential Tools for Jewelry Casting

Having the right tools will make the jewelry casting process much easier and more enjoyable. Here’s a list of essential tools you’ll need:

* **Casting Machine:** This is the heart of the casting process. Casting machines come in various types, including centrifugal casting machines, vacuum casting machines, and induction casting machines.

* **Centrifugal Casting Machine:** Uses centrifugal force to push the molten metal into the mold.

* **Vacuum Casting Machine:** Uses a vacuum to draw the molten metal into the mold, resulting in more detailed castings.

* **Induction Casting Machine:** Uses induction heating to melt the metal quickly and efficiently.

* **Burnout Oven:** A burnout oven is used to burn out the wax model from the investment mold. It needs to be capable of reaching high temperatures and maintaining a consistent temperature throughout the burnout cycle.

* **Melting Torch:** A melting torch is used to melt the metal in the crucible. Propane or butane torches are commonly used for smaller projects, while larger projects may require an acetylene torch.

* **Safety Gear:** Safety is paramount when working with molten metal. You’ll need safety glasses, heat-resistant gloves, and a respirator to protect yourself from burns, fumes, and dust.

* **Wax Carving Tools:** If you’re creating your wax model by hand, you’ll need a set of wax carving tools. These tools include wax files, wax saws, wax picks, and wax burs.

* **Investing Equipment:** You’ll need equipment for mixing and pouring the investment, including a mixing bowl, a vacuum chamber (optional), and a flask.

* **Finishing Tools:** Once your casting is complete, you’ll need tools for cleaning, polishing, and finishing the piece. These tools include files, sandpaper, polishing compounds, and a rotary tool.

### Product Recommendation: Rio Grande Jewelry Casting Starter Kit

For beginners, the Rio Grande Jewelry Casting Starter Kit is an excellent option. It includes many of the essential tools and materials you need to get started, saving you the time and hassle of sourcing everything separately.

* **Key Features:** Includes a centrifugal casting machine, burnout oven, crucible, investment, and basic safety gear.

* **Why We Like It:** This kit provides a comprehensive introduction to jewelry casting, making it perfect for beginners. It offers a good balance of quality and affordability.

[Browse top-rated jewelry casting on Amazon]

## Jewelry Casting Techniques: A Step-by-Step Guide

Now that you have your materials and tools, let’s walk through the jewelry casting process step-by-step:

### 1. Creating the Wax Model

The first step is to create a wax model of your jewelry piece. You can create the model by carving wax, injecting wax into a rubber mold, or using a combination of both techniques.

* **Carving:** Carving wax allows for precise and detailed designs. Use wax carving tools to shape the wax into your desired form.

* **Injection:** Injection wax is ideal for replicating existing designs. Inject the wax into a rubber mold and allow it to cool before removing the wax model.

### 2. Investing the Wax Model

Once you have your wax model, you need to invest it in a heat-resistant material. This creates a mold that can withstand the high temperatures of the burnout and casting processes.

1. **Mix the Investment:** Follow the manufacturer’s instructions to mix the investment powder with water. The consistency should be similar to pancake batter.

2. **Vacuum Degas (Optional):** Use a vacuum chamber to remove air bubbles from the investment mixture. This will result in a smoother casting.

3. **Pour the Investment:** Carefully pour the investment mixture into a flask, ensuring that the wax model is completely submerged.

4. **Allow to Set:** Allow the investment to set completely, typically for several hours or overnight.

### 3. Burnout the Wax Model

The next step is to burn out the wax model from the investment mold. This leaves a cavity in the mold that will be filled with molten metal.

1. **Place the Flask in the Burnout Oven:** Place the flask in the burnout oven and set the temperature according to the wax manufacturer’s instructions. A typical burnout cycle involves gradually increasing the temperature to around 1350°F (732°C) and holding it for several hours.

2. **Monitor the Burnout Process:** Monitor the burnout process to ensure that the wax is completely burned out and the investment mold is properly heated.

### 4. Melting the Metal

While the burnout process is underway, you can start melting the metal.

1. **Place the Metal in the Crucible:** Place the metal in the crucible and add flux to prevent oxidation.

2. **Heat the Crucible:** Heat the crucible with a melting torch until the metal is completely molten.

3. **Skim the Surface:** Use a stirring rod to skim any impurities from the surface of the molten metal.

### 5. Casting the Metal

Once the metal is molten and the burnout process is complete, you’re ready to cast the metal.

1. **Remove the Flask from the Burnout Oven:** Carefully remove the flask from the burnout oven using heat-resistant gloves.

2. **Position the Flask in the Casting Machine:** Position the flask in the casting machine according to the manufacturer’s instructions.

3. **Pour the Molten Metal:** Pour the molten metal into the flask, ensuring that it fills the cavity completely.

4. **Activate the Casting Machine:** Activate the casting machine to force the molten metal into the mold.

### 6. Quenching and Divesting

After the casting process is complete, you need to quench and divest the casting.

1. **Allow to Cool:** Allow the flask to cool for a few minutes before quenching it in water.

2. **Quench the Flask:** Quench the flask in water to rapidly cool the metal and break apart the investment.

3. **Divest the Casting:** Use a hammer and chisel to carefully remove the investment from the casting.

### 7. Finishing the Casting

The final step is to clean, polish, and finish the casting.

1. **Remove the Sprue:** Use a saw or rotary tool to remove the sprue (the metal that was used to pour the metal into the mold).

2. **File and Sand:** Use files and sandpaper to smooth any rough edges or imperfections.

3. **Polish the Casting:** Use polishing compounds and a rotary tool to polish the casting to a high shine.

[Browse top-rated jewelry casting on Amazon]

## Pro-Tips for Successful Jewelry Casting

Here are a few pro-tips to help you achieve successful jewelry castings:

* **Use High-Quality Materials:** Investing in high-quality materials will result in better castings and fewer problems.

* **Follow the Manufacturer

[Check the latest prices and deals for jewelry casting on Amazon today!]