[Get the best value casting jewelry on Amazon today!]

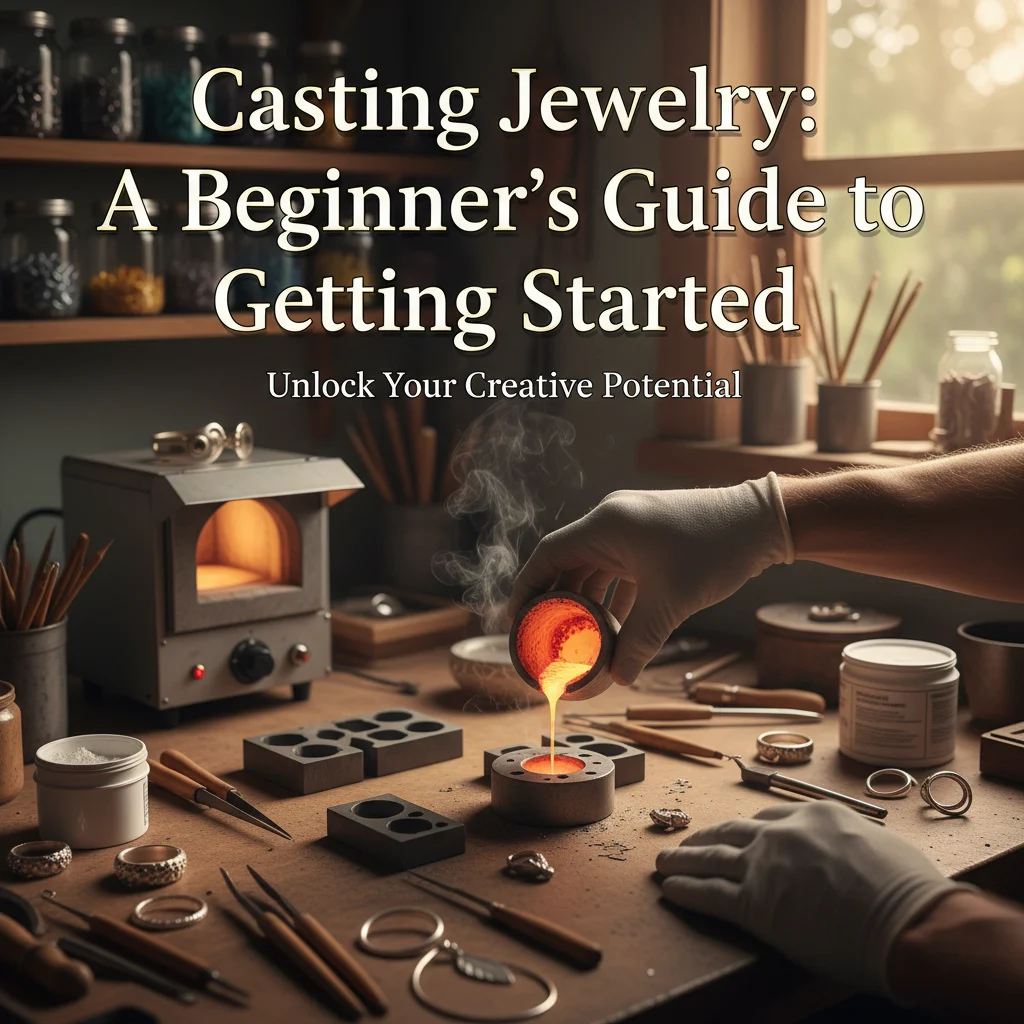

# Casting Jewelry: A Beginner’s Guide to Getting Started

So, you’re ready to dive into the fascinating world of casting jewelry? Fantastic! It’s a truly rewarding craft that allows you to bring your unique designs to life. But let’s be honest, getting started can feel a little overwhelming. Don’t worry, this guide is here to walk you through the process, step-by-step, and get you confidently creating your own cast jewelry in no time.

[Browse top-rated casting jewelry on Amazon]

## Why Casting Jewelry is So Rewarding

Casting jewelry unlocks a whole new level of creative freedom. Instead of relying on pre-made components, you can craft every single detail from scratch. Here’s why so many jewelers are drawn to this technique:

* **Unlimited Design Potential:** Want to create a ring with a unique texture? A pendant in an unusual shape? Casting allows you to make it happen.

* **Control Over Materials:** You get to choose the exact metals you want to work with, ensuring the quality and purity of your pieces.

* **Repeatability:** Once you have a mold, you can create multiple copies of the same design, perfect for building a collection or fulfilling orders.

* **Professional Results:** Cast jewelry has a polished, professional look that’s hard to achieve with other techniques.

[Browse top-rated casting jewelry on Amazon]

## The Solution: Investing in the Right Tools and Techniques

Casting jewelry might seem complex, but it breaks down into manageable steps. The key is to understand the process and invest in the right tools. This guide will cover the essential techniques and recommend some quality products to get you started.

### Step 1: Creating Your Model

The first step in casting jewelry is creating a model, also known as a pattern. This is a replica of the piece you want to cast, and it can be made from various materials like wax, resin, or even 3D-printed plastic.

* **Wax Models:** Wax is a popular choice for its ease of carving and shaping. You can use specialized wax carving tools to create intricate details.

* **Resin Models:** Resin is more durable than wax and can be used for more complex designs.

* **3D-Printed Models:** 3D printing allows you to create highly detailed models with incredible precision.

### Step 2: Investing the Model

Once you have your model, the next step is to invest it. This involves creating a mold around the model using a special type of plaster called investment powder.

1. **Mixing the Investment:** Mix the investment powder with water according to the manufacturer’s instructions. It’s crucial to get the ratio right to ensure a strong and durable mold.

2. **Investing the Model:** Place the model in a flask (a metal cylinder) and pour the investment mixture over it, making sure to cover it completely.

3. **Vacuuming the Flask:** Use a vacuum chamber to remove any air bubbles from the investment. This will prevent imperfections in the final casting.

**Tools for the Job:**

* **Investment Powder:** *Satin Cast 20 Investment Powder* is a high-quality investment powder that’s known for its smooth finish and resistance to cracking.

* **Key Features:** Consistent mixing, smooth surface, minimal cracking.

* **Why We Like It:** This investment powder consistently delivers excellent results, making it a reliable choice for beginners. It minimizes the risk of imperfections and ensures a smooth casting.

* **Vacuum Chamber:** *VEVOR 3 Gallon Vacuum Chamber Kit* is a compact and affordable option for degassing investment and resins.

* **Key Features:** Durable construction, easy to use, effective degassing.

* **Why We Like It:** Removing air bubbles is crucial for a flawless casting, and this vacuum chamber makes the process simple and efficient. It’s a great investment for achieving professional-quality results.

### Step 3: Burnout

After the investment has hardened, the next step is to burn out the model. This involves heating the flask in a burnout oven to melt or vaporize the model, leaving a hollow cavity in the investment.

1. **Burnout Oven:** Place the flask in a burnout oven and follow a specific burnout schedule. This schedule typically involves gradually increasing the temperature over several hours to ensure that the model is completely removed without damaging the investment.

2. **Temperature Control:** Accurate temperature control is essential for a successful burnout. The burnout schedule will vary depending on the material used for the model.

### Step 4: Melting the Metal

While the flask is still hot from the burnout process, it’s time to melt the metal that you’ll be using for your casting jewelry.

1. **Melting Furnace:** Use a melting furnace to heat the metal to its melting point. The type of furnace you use will depend on the type of metal you’re working with.

2. **Flux:** Add flux to the metal to help remove impurities and prevent oxidation.

3. **Safety Precautions:** Always wear appropriate safety gear, including gloves and eye protection, when working with molten metal.

### Step 5: Casting

Once the metal is molten, it’s time to cast it into the mold. There are several different casting methods you can use, including:

* **Centrifugal Casting:** This method uses centrifugal force to push the molten metal into the mold.

* **Vacuum Casting:** This method uses a vacuum to draw the molten metal into the mold.

* **Lost Wax Casting:** The most common method for jewelry making, involving the steps mentioned above.

1. **Pouring the Metal:** Carefully pour the molten metal into the flask, making sure to fill the cavity completely.

2. **Cooling:** Allow the metal to cool completely before removing it from the flask.

**Tools for the Job:**

* **Melting Furnace:** *SHZOND Digital Electric Melting Furnace* is a reliable and easy-to-use furnace for melting gold, silver, and other metals.

* **Key Features:** Digital temperature control, rapid heating, compact design.

* **Why We Like It:** This furnace offers precise temperature control, ensuring that your metal is melted to the perfect temperature for casting. Its compact design makes it ideal for small workshops.

### Step 6: Quenching and Divesting

After the metal has cooled, quench the flask in water. This will help to break down the investment and make it easier to remove the casting.

1. **Quenching:** Carefully quench the flask in a bucket of water. Be prepared for a burst of steam!

2. **Divesting:** Use pliers and a brush to remove the remaining investment from the casting.

### Step 7: Finishing

The final step in casting jewelry is finishing the piece. This involves removing any imperfections, polishing the metal, and adding any desired details.

1. **Removing Sprue:** Cut off the sprue (the excess metal that was used to pour the metal into the mold).

2. **Filing and Sanding:** Use files and sandpaper to smooth out any rough edges or imperfections.

3. **Polishing:** Polish the metal to a high shine using a polishing wheel and compound.

4. **Adding Details:** Add any desired details, such as gemstones or enamel.

[Browse top-rated casting jewelry on Amazon]

## Pro-Tips / FAQ Section:

* **What type of wax should I use?** There are many different types of wax available, each with its own unique properties. Experiment with different waxes to find one that you like working with. * Ferris File-a-Wax* is a great start.

* **How do I prevent porosity in my castings?** Porosity (small bubbles in the metal) is a common problem in casting. To prevent porosity, make sure to use a vacuum chamber to remove air bubbles from the investment, and use a flux when melting the metal.

* **How do I get a smooth finish on my castings?** A smooth finish starts with a smooth model. Make sure to sand and polish your model before investing it. Also, use a high-quality investment powder and follow the burnout schedule carefully.

* **What is the best temperature for burnout?** The ideal burnout temperature depends on the type of wax or resin used for your model. Always consult the manufacturer’s instructions for the specific material you’re using. Generally, a range of 1350°F (732°C) is suitable for most waxes.

* **Can I cast different metals?** Yes, you can cast a variety of metals, including gold, silver, bronze, and copper. However, each metal has its own melting point and casting characteristics, so you’ll need to adjust your techniques accordingly.

[Browse top-rated casting jewelry on Amazon]

## What to Look For When Buying Casting Jewelry Equipment

Choosing the right equipment can make or break your casting jewelry experience. Here’s what to consider:

* **Quality:** Invest in high-quality equipment that is built to last.

* **Features:** Look for equipment with features that will make your job easier, such as digital temperature control and vacuum chambers.

* **Price:** Don’t necessarily go for the cheapest option. Consider the long-term value and durability of the equipment.

* **Reviews:** Read reviews from other jewelers to get their opinions on different products.

[Browse top-rated casting jewelry on Amazon]

## Encouraging Conclusion:

Casting jewelry is a rewarding and creative process that allows you to bring your unique designs to life. While it may seem daunting at first, by following these steps and investing in the right tools, you’ll be creating beautiful, professional-quality jewelry in no time. So, gather your materials, fire up your imagination, and get ready to embark on a journey

[Check the latest prices and deals for casting jewelry on Amazon today!]